HD COB Display–The New Display Technology of Future

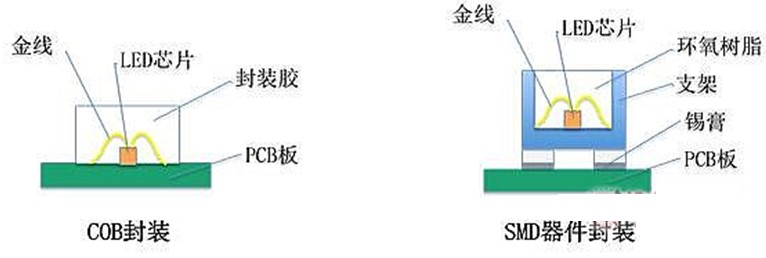

COB technology is an emerging LED packaging technology. Different from traditional SMD surface-mount packaging, it integrates light-emitting chips into the PCB board instead of welding them to the PCB one by one. COB effectively improves the reliability, light color, and protective performance of LED displays. Now, follow us to learn more about COB LED displays!

Features of COB LED display

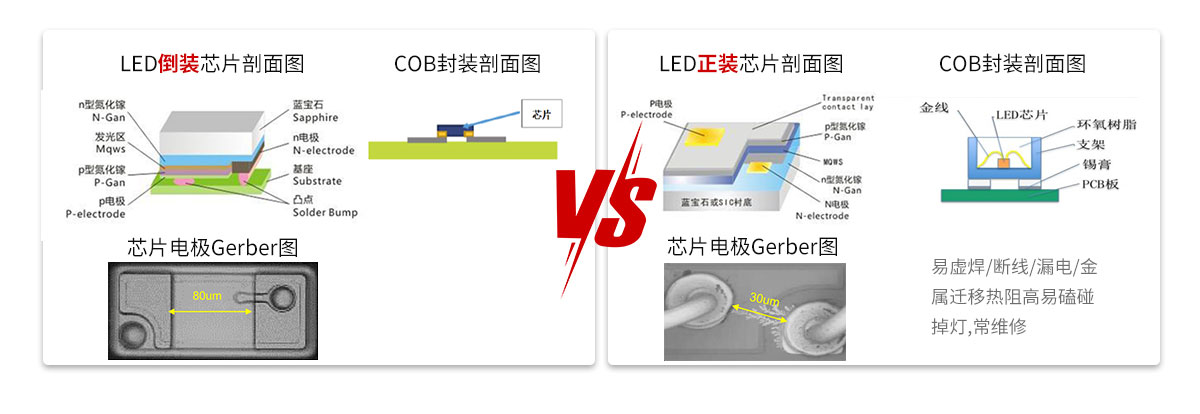

COB technology comparison

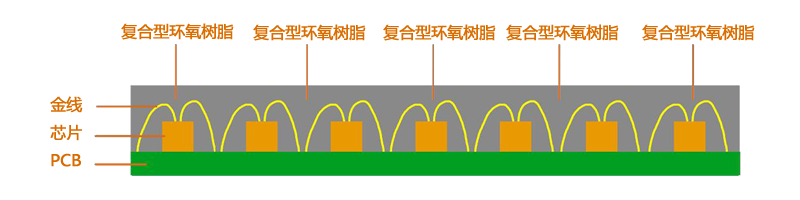

COB formal assembly process (conventional process in the industry)

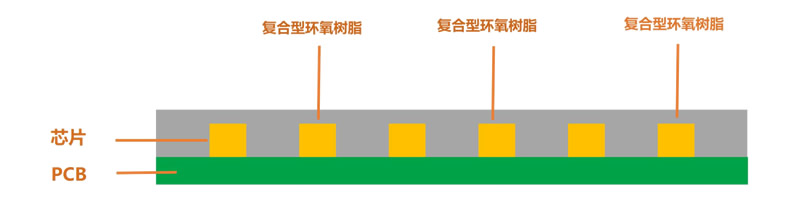

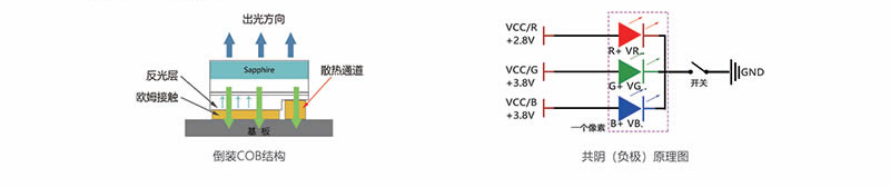

COB common cathode flip-chip process (Chinastar LED Technology)

1) COB flip-chip technology means that the electrodes of the flip-chip face downwards and do not require the lead stitching and welding process of the regular chip. In this way, the active layer is closer to the substrate, shortening the heat flow path from the heat source to the substrate, and has lower thermal resistance. , which can greatly improve product stability.

2) “Common cathode” refers to the use of common cathode to power the LED display. For products with the same specifications and the same brightness, the power consumption of the common cathode LED display is about 40% lower than that of conventional LED display products, and the energy consumption is reduced.

Advantages of COB display

COB (Chip on Board) display has the following 10 major advantages:

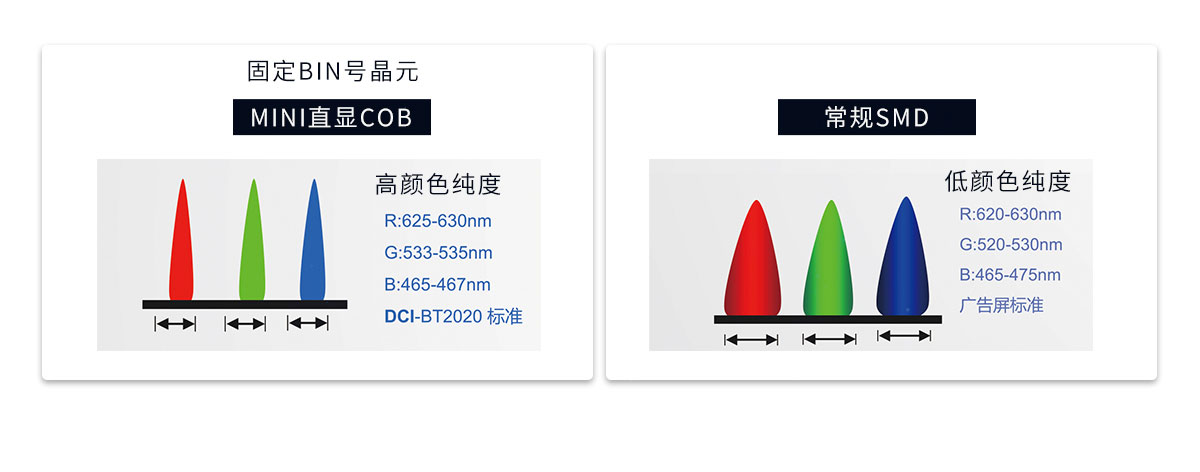

1) MINI flip-chip COB technology: COB technology uses the MINI flip-chip process to achieve a compact arrangement of chip packages and improve the overall performance of the screen.

2) High contrast: COB display screen can achieve higher contrast, making the image clearer and the color fuller during display.

3) Consistent color: COB technology ensures the consistency of the LED chip, making the color performance of the entire display more uniform and consistent.

4) DCI color gamut: The COB display supports the DCI color gamut standard, providing a wider color range and making the displayed images more realistic.

5) Low-consumption cold screen: The COB display adopts low-consumption cold screen technology, which effectively reduces energy consumption and extends the service life of the screen.

6) Moisture-proof, scrubbable, and anti-static: The COB display is moisture-proof, scrubbable, and anti-static. It is suitable for a variety of environments and improves the stability and durability of the screen.

7) Panel hardness 4H, anti-bump: The hardness of the display panel reaches 4H, which is anti-scratch and anti-bump, increasing the durability of the display.

8) Matte matte, consistent ink color: The matte matte treatment makes the screen surface softer, and the ink color performance is consistent, providing a better visual experience.

9) Integration: The COB display realizes the integrated design of the chip, reducing the size of the display and simplifying the manufacturing process.

10) Precision splicing: COB technology makes the arrangement of LED chips more compact, realizes precise splicing of the screen, and improves the uniformity and clarity of the overall display effect.

The difference between COB display and LED screen

Many customers who come into contact with LED often hear about COB technology and are confused about how it is different from traditional LED displays. In fact, what we call C0B is an emerging LED display packaging technology. In the past, LED displays SMD surface mount packaging is used, so the comparison between COB display screen and LED display screen is actually the comparison between SMD packaging and COB packaging. What is the difference between the two?

- Differences in packaging technology

Conventional LED screens are packaged in surface-mounted SMDs. The technical process is cumbersome and requires a certain amount of operation time. The minimum point spacing can only be 1.2. Even if the all-in-one can be made smaller, it still cannot get rid of the problem of falling lights. COB packaging simplifies the packaging process of LED chips. The LED chips are directly integrated on the PCB board and fixed with glue. The process is simpler and does not require reflow soldering. The LED chips are also more stable and the point spacing can be smaller.

- Difference in stability

Conventional LED display lamp beads are welded on the PCB board, and the lamps can easily fall off when collided. If you want to repair it, technicians can only go to the site to weld or directly replace the unit board, resulting in a high after-sales rate. The COB display screen has better packaging protection and better anti-collision ability. It will not cause the lamp beads to fall during installation and use, and the stability is greatly improved.

- The difference between dot spacing

Conventional LED displays are limited by packaging technology. The pixel pitch is usually P1.2 and above, such as P1.2, P2.0, P3, P4, etc. Its development limitation is that it cannot achieve a pixel pitch below 1.2, resulting in screen The resolution cannot be further improved, so it is not suitable for use if the requirements for image quality and clarity are relatively high. The COB display screen can achieve smaller pixel pitch. For example, the P1.2 and P0.9 products provided by Chinastar are all packaged in COB. The technology is mature and the picture clarity is higher.

The main difference between cob display screen and led display screen is the above three points. From the perspective of industry development, COB screen will be the mainstream direction in the future. Compared with the display screen of traditional surface mount technology, COB display screen has high reliability, It has many advantages such as low cost, small spacing, wear resistance and impact resistance, and strong heat dissipation ability.

Craftsmanship of COB LED display

Here’s 6 major process flows of COB display: material preparation-substrate processing-chip pasting-soldering-packaging-testing

1.Material preparation

Including metal substrates, LED chips, packaging materials, wires, etc. Among them, LED chips are the core components of the COB process, and their quality and performance directly affect the overall packaging quality. Packaging materials are generally used

- Substrate processing

The metal substrate is treated to remove dirt and oxygen to ensure the cleanliness and smoothness of the substrate surface. Then, apply a layer of thermally conductive glue on the substrate to improve the heat conduction effect between the LED chip and the substrate.

- Chip pasting

Paste the LED chip on the treated metal substrate. When pasting, attention should be paid to the positioning and arrangement of the chips to ensure uniform distribution of light and maximize light efficiency. After the pasting is completed, special equipment is used to control the pressure and temperature to tightly combine the chip with the substrate.

- Welding

After the chip is pasted, the circuit between the chip and the substrate is connected by soldering wires. When welding, the welding temperature and welding time need to be controlled to avoid damage to the chip and substrate.

- Encapsulation

After the packaging material is pre-treated, it is covered on the chip and substrate using a specific method. The selection of packaging materials should take into account factors such as their mechanical properties, heat resistance and weather resistance. After the encapsulation is completed, curing processing is required to ensure the firmness and stability of the encapsulation material.

- Testing and quality inspection

By conducting electrical performance testing, optical performance testing and reliability testing on packaged LED products, we ensure that the quality and performance of the product meet the requirements. At the same time, appearance inspection and packaging are also required to meet market demand.

Advantages and Disadvantages of COB and SMD

For LED displays, COB and SMD are both packaging methods. COB directly packages the light-emitting chip on the PCB board, while SMD refers to surface mounting. Both of these have their own advantages and disadvantages:

SMD packaged LED display–Advantages:

- Can produce displays that are thinner, brighter, and clearer than LCDs

- Power consumption is 10/1 of LCD display

- High brightness

- Viewing angle 160°

- High refresh rate, contrast, better display and better product performance

- Can be viewed normally under strong light

- The reaction of a single element is 1,000 times that of an LCD screen

- -30°C-80°C can be used normally

- Waterproof, moisture-proof, anti-static, dust-proof, lightning-proof, anti-static

- There are many types of spacing, suitable for various usage environments.

- Various shapes can be assembled at will

- Long life (more than 10 years)

SMD packaged LED display – Disadvantages:

- The brightness is too high and long-term viewing can easily cause eye fatigue.

- It feels grainy when viewed from a close distance.

- Lamp beads may be damaged during transportation.

- The heat dissipation capacity is not strong enough

- There is a big difference between the spacing

- Difficult to clean

COB packaged LED display–Advantages:

- Small spacing, smooth screen surface, and clearer display (preferred below P1.0)

- The picture is soft and bright, and it won’t hurt your eyes when you watch it for a long time.

- Contrast ratio 10000:1, superior picture quality

- Refresh rate ≥3840Hz, a symbol of high quality among similar products

- Anti-collision and impact resistance, the load-bearing capacity is more than 5 times that of the LED display, and it is not afraid of collisions, broken lights and other problems during transportation.

- Good heat dissipation ability, heat is quickly dissipated directly through the PCB board

- Effectively suppress moiré patterns

- Super large viewing angle 170°

- Waterproof, moisture-proof, anti-static, dust-proof, lightning-proof, anti-static, anti-collision

- Can be used normally at -40°C-80°C

- Easy to clean

- Long life (more than 10 years)

COB packaged LED display – Disadvantages:

- High price

- The technologies of each enterprise are uneven.

- The screen appearance is not as good as LED small pitch

- The production process is different from SMD packaging, and the transformation cost is high.

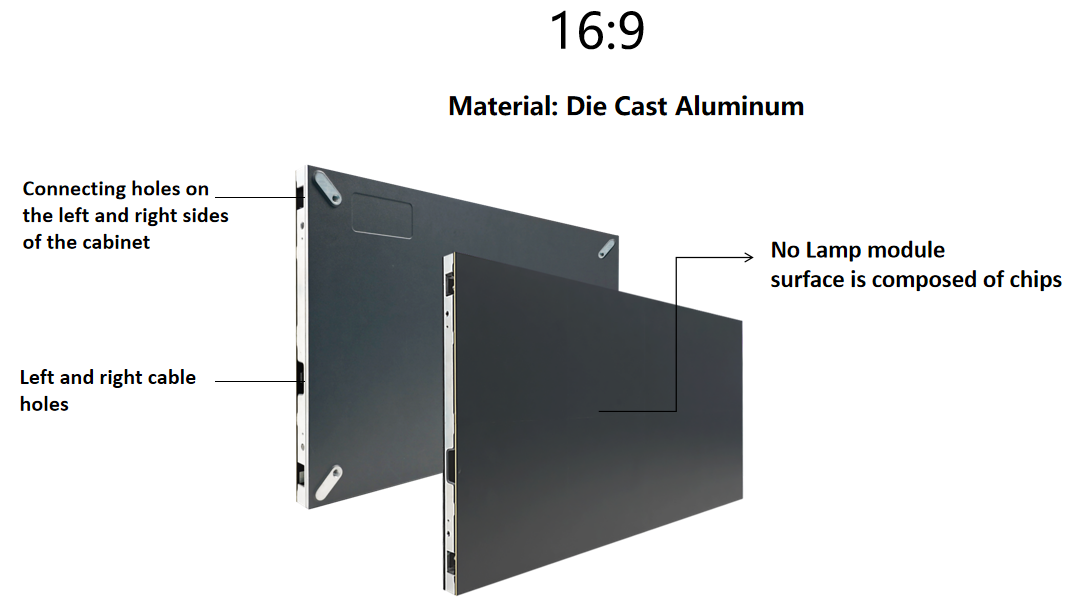

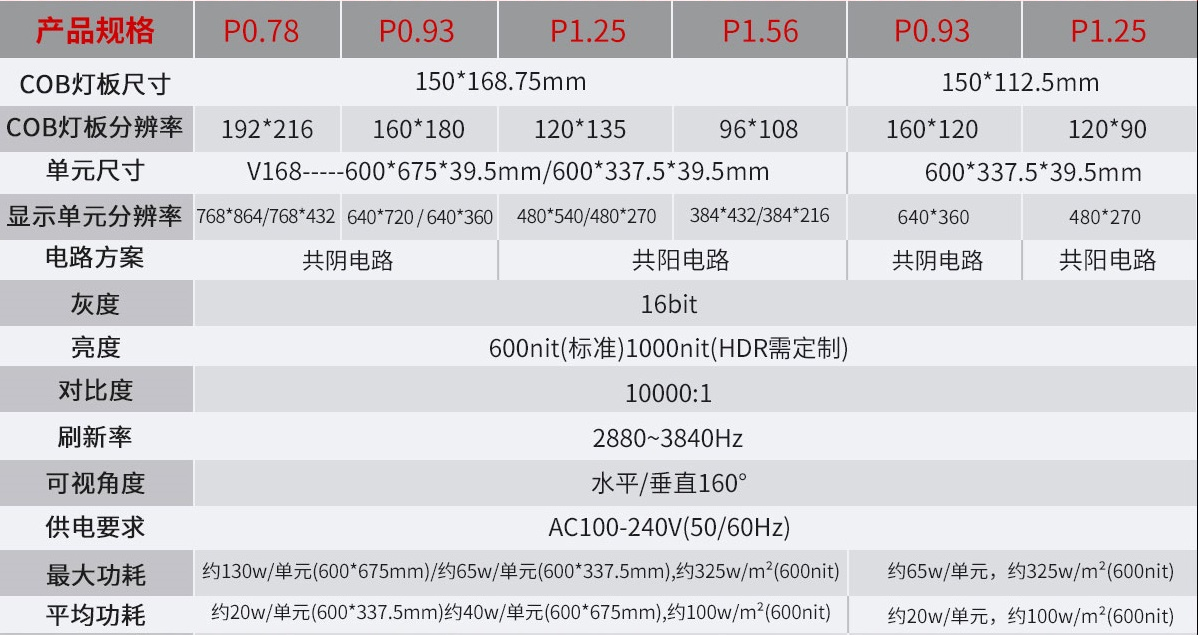

Chinastar COB LED Screen Recommend

- long life

- Little fever

- Good heat dissipation

- Small light attenuation

- Completely front-maintenance design

- Point-to-point matching, 2K/4K/8K resolution

- Three point spacings are available: 0.93, 1.25, and 1.56.

- Waterproof, dustproof, anti-oxidation, anti-static, anti-impact

- High brush and low gray, refresh frequency up to 3840Hz, grayscale 16Bit

- The full flip-chip process is equipped with a common cathode solution, which has good stability, low consumption and energy saving

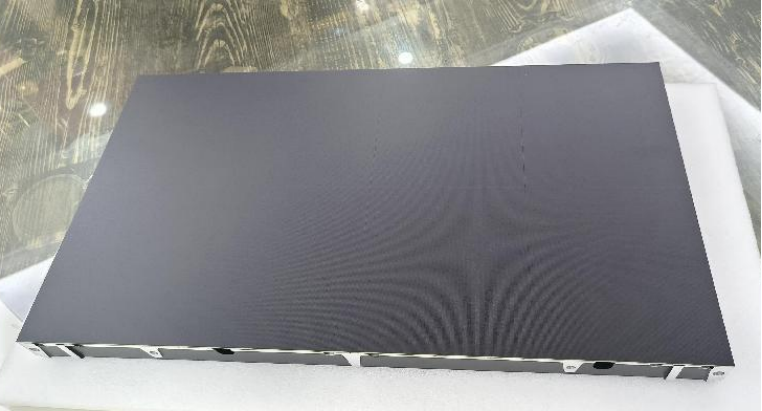

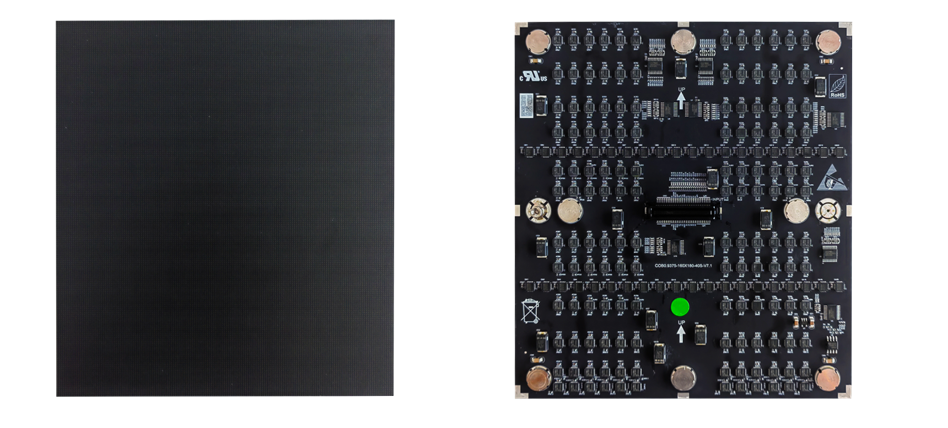

Module

Module Dimension: 150×168.75mm Brightness:600~800CD

Module Thickness:2mm Module surface:Composed of chips

AGING TEST

Currently, COB displays face some challenges in the popularization process. Part of the reason is that the transition from SMD packaging requires the replacement of original equipment, which may lead to waste. In addition, companies may face large differences when adopting COB technology. However, our company adopts a unique production process that allows their COB display products to have high yields. If you have needs for COB displays or want to know more details, please contact Chinastar LED.

Send Us An Message

High-quality products, superb technology