When comparing the cabinet structure and module structure of LED display screens, it is necessary to make comprehensive considerations from multiple dimensions, including display effect, installation and maintenance, cost, stability, and application scenarios. The following is a detailed analysis of the two structures:

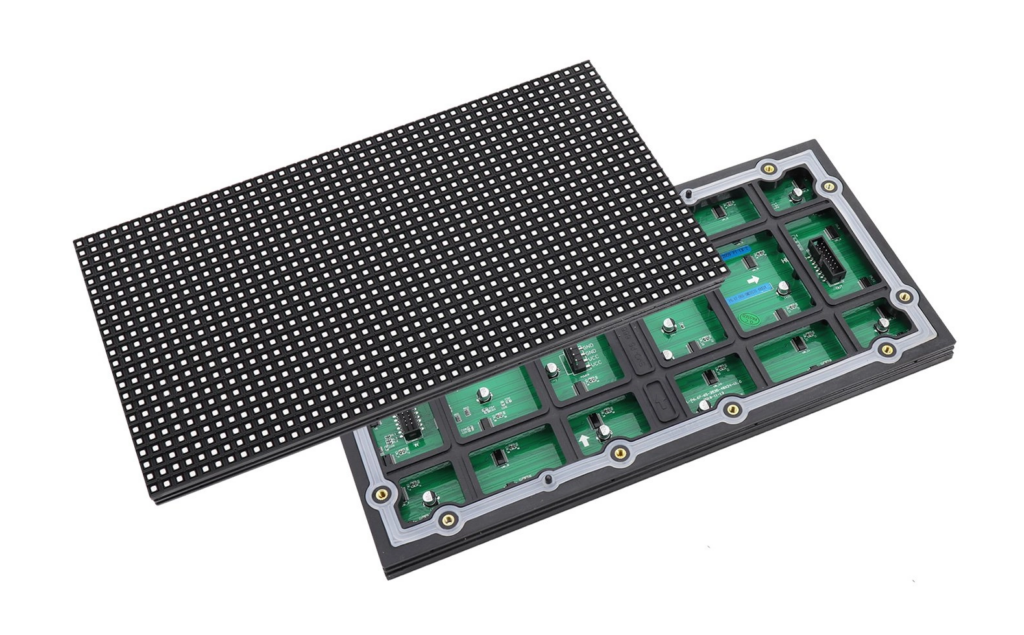

LED Display Module

Led Cabinet

一、Display Effect

- Box structure:

Box structure usually has a larger size, so the number used in a display screen is small, and the overall flatness can be better guaranteed when splicing, so the display effect will be better.

The display screen with box structure usually has a smaller splicing gap, which helps to improve the integrity and continuity of the picture.

- Module structure:

Due to its small size, the module structure is used in a large number of display screens. Manual splicing may cause some defects in the splicing and flatness, especially in large-area display screens. However, the module structure also has the advantage of high flexibility, and the size and resolution of the screen can be customized according to specific needs.

二、Installation and maintenance

- Box structure:

The box structure is usually more stable, and multiple screws are generally used to fix it during installation, which is not easily affected by external factors.

The design of the box structure makes maintenance more convenient, especially when there is no maintenance space on the back of the display, the box structure can be easily opened for maintenance.

- Module structure:

The module structure is relatively flexible during installation, but the back needs to be closed separately, which may increase the complexity of installation.

If a module fails, it can be replaced separately without affecting the overall use, but this also requires a certain level of technical skills and experience.

三、Cost

- Cabinet structure:

The cabinet structure is highly integrated, and the cabinet itself is often made of high-quality materials such as die-cast aluminum, so the cost investment will be slightly higher. However, in the long run, the stability and durability of the cabinet structure may make its maintenance cost relatively low.

- Module structure:

The cost of the module structure is relatively low because the initial investment in purchasing modules and accessories separately may be low.

However, if the later maintenance costs and possible replacement costs are taken into account, the total cost of the module structure may rise.

四、Stability

- Cabinet structure:

The cabinet structure usually performs better in terms of stability and durability, especially in harsh environments.

The use of high-quality materials such as die-cast aluminum further improves the stability and durability of the cabinet structure.

- Module structure:

The module structure may be slightly deformed due to factors such as thermal expansion and contraction during long-term use, thus affecting the display effect and stability.

However, if high-quality modules and accessories are used and regularly maintained, the stability of the module structure can also be improved to a certain extent.

五、Application scenarios

- Cabinet structure:

The cabinet structure is usually suitable for outdoor display screens, large display screens, and occasions with high requirements for display effects and stability. Especially in occasions where frequent maintenance and repairs are required, the advantages of the cabinet structure are more obvious.

- Module structure:

The module structure is more suitable for indoor display screens, small-area display screens, and occasions with high requirements for flexibility and customization. If the budget is limited and there are certain technical capabilities, the module structure is also a good choice.

In summary, the cabinet structure and module structure of LED display screens have their own advantages and disadvantages. When choosing, it is necessary to comprehensively consider factors such as specific application scenarios, budgets, technical requirements, and maintenance costs.